Oil and gas software is at the core of safe and efficient operations. Offshore platforms, refineries, and pipelines all run under demanding conditions where every detail matters. Even a brief delay can cause costly downtime, and a small oversight can put both safety and performance at risk.

In this environment, oil and gas software solutions are more than just background support. It provides the visibility, data, communication, and control companies need to ease coordination, improve operational efficiency, and protect workers. Heavy machinery may power production, but it’s digital systems that connect everything and make sure the work gets done reliably and safely.

In this article, we’ll look at how oil and gas software helps organizations overcome everyday challenges, improve safety, and respond effectively when critical moments arise.

Table of Contents

Common Pain Points in Oil and Gas Safety

Even with the best training and safety protocols, oil and gas operations face consistent challenges that put people and production at risk:

- Maintenance and human error: Annual maintenance shutdowns almost always bring a rise in incidents. With so much work happening at once and the pressure to get everything done quickly, even small errors slip through, and human error remains the leading cause.

- Technology failures: When software malfunctions, the consequences can be dangerous. A single overlooked process, such as a valve left under pressure, can increase cost, reduce productivity, and even put lives at risk.

- Low trust in safety features: Fall detection systems are built to save lives, but constant false alarms quickly undermine trust. Once workers stop believing the alerts, they stop using them, and that leaves crews without protection when it’s needed most.

- Specialized equipment requirements: During maintenance, workers are often restricted to using specific hardware that minimizes the risk of sparks. While essential for safety, it complicates operations and slows workflow.

- Regulatory compliance: Meeting compliance means keeping records precise and up to date. Software with automation makes it easier to generate every required report, reducing the burden on teams and ensuring nothing is missed.

Protecting People, Not Just Processes: The Role of Oil and Gas Software

When technology is discussed in meeting rooms, the focus is often on performance, data, or efficiency. But for people working in energy companies, priorities look very different.

What matters most is knowing that help is always within reach. It’s having the confidence that their location is visible if something goes wrong, that their calls for support will be heard, and that clear instructions will guide them through critical moments.

This is where oil and gas software solutions, especially emergency management platforms, deliver innovation and service that go beyond dashboards and analytics. They provide reassurance, connection, and protection. At its core, it’s not about numbers on a screen. It’s about safeguarding lives, improving reporting transparency, and giving workers the confidence that they are never facing risks alone.

Logistics and Daily Coordination: The Hidden Challenge

Day-to-day operations in oil and gas rarely run on autopilot. Deliveries have to arrive on time, contractors need to be managed across shifts, and crews are moved to remote sites by air or road. With so many moving parts, even a small disruption can quickly throw schedules off balance.

In moments like this, connected systems play a key role. By improving operational performance and giving managers a clear view of assets and resources, software helps avoid disruptions and supports smoother business processes. Clear communication across teams ensures challenges are addressed before they spread, and user-friendly interfaces make it easier for crews in the field to share updates instantly. And when conditions shift from routine to urgent, the same technology ensures everyone is ready to respond without hesitation.

Emergency Response: When Seconds Decide Everything

It’s an ordinary afternoon at the refinery. The routine continues until alarms signal a gas leak by one of the storage tanks. Sirens follow, guiding workers to evacuate. In the control room, the focus shifts to making the right decisions without delay.

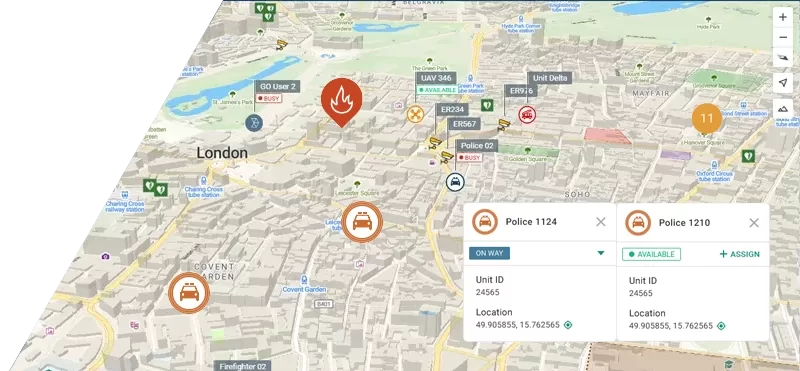

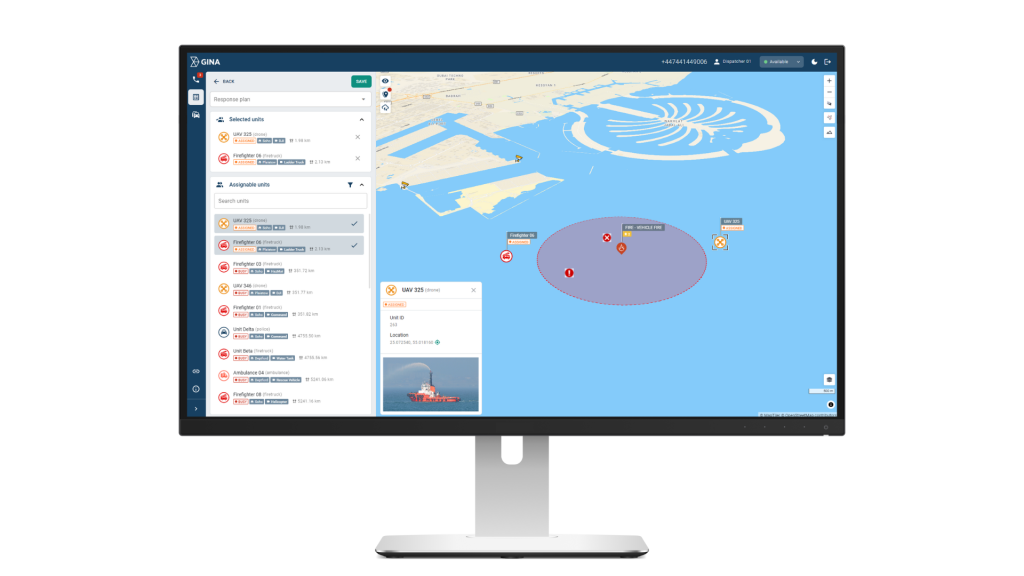

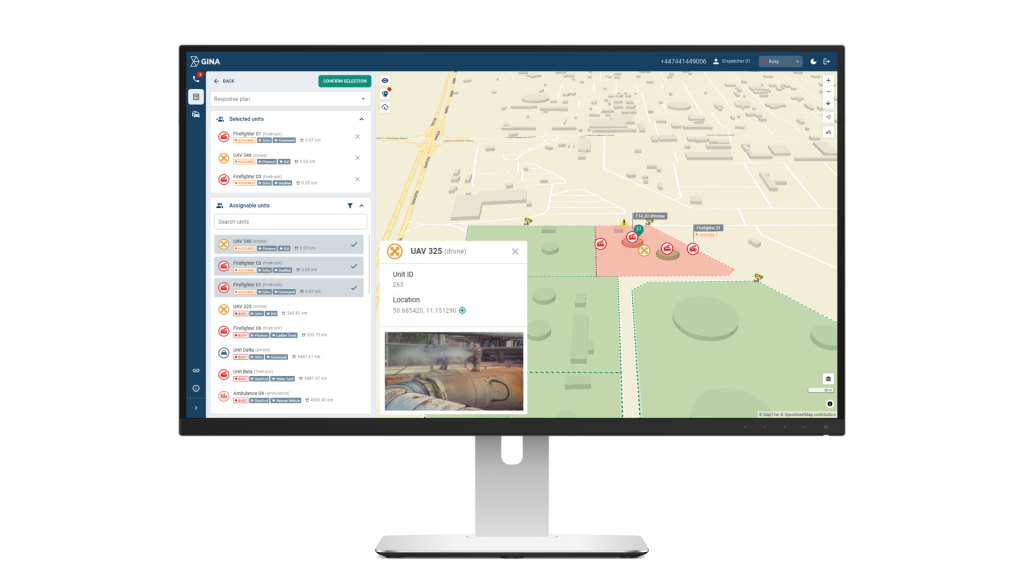

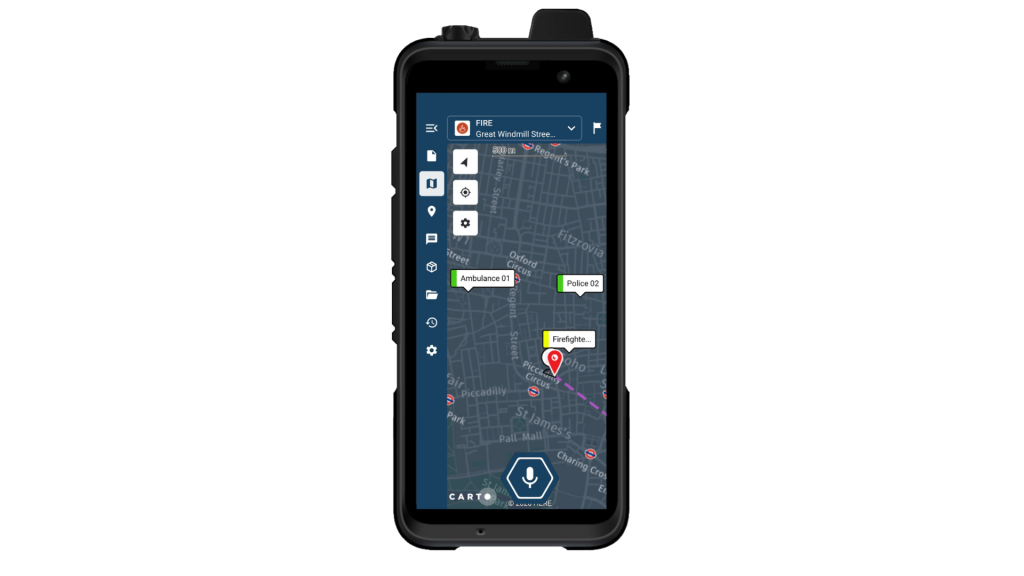

With Smart CAD (Computer-Aided Dispatch), the response unfolds in a structured way instead of chaos. Some of the key features of Smart CAD are:

- Automatic alerts from sensors and geofences: Gas detectors and perimeter sensors feed directly into Smart CAD, instantly identifying the source of the problem and the affected zone.

- Live map of people and vehicles: GPS tracking of workers and response units show their exact positions. Commanders see in real time who is safe, who is in danger, and which teams are closest.

- Smart dispatching of the right units: Instead of guessing who to send, the system uses automation to suggest the best response teams based on proximity, training, and available equipment.

- Multimedia sharing: Photos of the leaking valve, video from drones, and sensor readings flow into Smart CAD, giving decision-makers a full picture of the incident and helping them allocate resources more effectively.

- Camera and drone visibility: Fixed-site cameras provide live video streams. Drones, even with thermal imaging, can be launched to monitor the situation in areas unsafe for people.

- SOS button for field staff: If someone is trapped or needs urgent help, they can trigger an SOS from their device. Their location appears immediately in the system, prioritizing the rescue and sending the right help immediately.

- Instant push-to-talk communication: One tap connects the control room to every unit in the field, ensuring instructions are clear and immediate.

- Dynamic navigation: Response vehicles are guided along the fastest and safest routes, automatically rerouted if roads are blocked or conditions change.

The difference is clear. What might have turned into chaos instead becomes a coordinated response. Workers leave the site quickly, responders act with focus, and the leak is secured before it grows worse.

Smart CAD brings everything together, sensors, cameras, trackers, and human alerts, into one clear operational picture. And when every second matters, that clarity is what saves lives.

Want to see how this works in real-world conditions? Visit our oil and gas landing page for examples of Smart CAD in action, from remote sites to large-scale refineries.

After the Incident: Learning and Prevention

But the story doesn’t end once the alarms go quiet. Every evacuation, every dispatch, and every decision is automatically recorded, creating a complete record of the event. For leaders, this information is a powerful resource.

Regulatory reporting can be generated instantly, with clear timelines that show exactly how the incident unfolded. Patterns in response times or repeated risks become visible, giving safety managers data-driven insights that no amount of guesswork could provide.

Training programs also benefit. Instead of relying on theory, they can be shaped by real performance in real situations. Preventive measures, too, are far stronger when they’re based on evidence rather than assumptions.

In this way, each incident becomes more than a disruption. It becomes a chance to improve safety, strengthen processes, and build lasting resilience.

Stronger, Faster, Safer with Technology

The oil and gas industry will never be without risk. What sets resilient companies apart is how well they prepare, how effectively they respond, and how consistently they learn from every event.

With the right oil and gas software, such as Smart CAD, uncertainty is replaced by clarity. Teams who might otherwise be isolated stay connected. Decisions that once took minutes can be made in seconds. And every emergency becomes a chance to strengthen safety and improve processes.

In a sector where downtime is costly and safety is always a priority, investing in the right software platform is about more than technology. It’s about strengthening resilience, supporting workers, and keeping operations reliable under pressure.

Ultimately, success in oil and gas is not only measured in production or revenue. It is also reflected in the assurance that, when challenges arise, companies have the right tools in place to protect their people and maintain steady operations.