Oil and gas safety management is the backbone of safe, reliable, and efficient operations in one of the world’s most high-risk industries. From offshore operations to onshore refineries, companies face many challenges – complex infrastructure, heavy machinery, hazardous material, and demanding environments. In these conditions, even a small incident can lead to severe consequences.

Effective safety management is not only about meeting regulatory requirement – it’s about protecting people, preventing hazards, and ensuring the long-term resilience of operations.

In this article, we’ll explore the key elements of oil and gas safety management, the everyday challenges companies face, and how digital solutions such as Smart CAD are transforming the way organizations keep their workers safe.

Table of Contents

Everyday Challenges in Oil and Gas Safety Management

In the oil and gas industry, some of the most serious risks don’t come from rare disasters but from routine activities. Planned maintenance, for example, may look structured, but it often disrupts normal workflows. Equipment is taken offline, crews follow unfamiliar steps, and even a single overlooked action during restart can lead to an incident.

Technology, while essential, can sometimes create new risks of its own. When monitoring systems fail to communicate properly or alarms don’t trigger as expected, critical details can be missed. A small oversight, like a valve left under pressure, can put workers in danger.

And then there are the human factors. Safety technologies such as fall detection or wearable alarms are only effective if people trust them. Frequent false alerts cause workers to ignore them, and once trust is lost, rebuilding it is difficult.

Even the devices workers carry can create risks. In high-risk zones, standard phones or radios might spark, so only certified equipment can be used. Without software that runs seamlessly on these devices, coordination slows, and blind spots appear.

Behind every operational challenge stands the weight of safety regulations. Companies must keep precise reports, maintain detailed records, and prove accountability. While essential, these demands often place additional pressure on already complex processes.

Building Strong Safety Foundations

The first step in effective safety management is clear standards. These set the foundation for operations, ensuring consistency across sites while aligning with both local and international regulations. Without standards, safety becomes fragmented and unreliable.

Equally important is safety training. Workers need more than written instructions; they need the confidence and skills to act when it matters most. Fire drills, emergency shutdown exercises, and hazard simulations turn procedures into instinctive reactions. A well-prepared team can respond quickly, limit risks, and keep incidents from escalating.

Technology also plays a growing role in strengthening these foundations. Software platforms now help teams standardize procedures, track training records, and ensure compliance across sites. By embedding safety protocols into digital workflows, companies make it easier for workers to follow best practices and for managers to monitor performance. This combination of clear standards, practical training, and smart technology creates a reliable framework for safer, more resilient operations.

Offshore Operations: Risks and Realities

Offshore operations present unique challenges for safety compliance. Harsh weather, isolated worksites, and complex infrastructure mean that safety hazards can escalate quickly. Regulatory requirements in these environments are strict for good reason – they are designed to protect workers in some of the most demanding conditions.

By applying robust safety protocols, companies can reduce risks and prepare teams to respond effectively to emergencies. Whether it’s fire safety systems, evacuation procedures, or continuous hazard monitoring, strong planning ensures offshore operations remain as safe and reliable as possible.

From Compliance to Continuous Improvement

Meeting regulatory requirements is non-negotiable, but true safety management goes further. Companies that excel in worker safety and industrial safety adopt a proactive approach: they analyze safety incidents, review protocols, and update practices for continuous improvement.

Regular safety audits also play an important role here. They provide an objective view of how well standards are being followed, identify gaps before they become risks, and ensure that improvements are actually being implemented across sites. By treating audits not just as compliance exercises but as opportunities for learning, organizations strengthen both accountability and resilience.

The Power of Digital Solutions

Modern digital platforms are transforming how safety professionals work. Integrated tools give teams real-time visibility into operations, helping them spot safety hazards before they escalate. Features such as automated alerts, digital reporting, and streamlined documentation simplify compliance while strengthening hazard prevention.

With process automation and real-time monitoring, safety protocols can be built directly into workflows, ensuring that worker safety is protected at every step. For companies balancing efficiency with safety, these tools provide a clear advantage, making operations safer, more reliable, and easier to manage.

Smart CAD: Coordinating Safety in Real Time

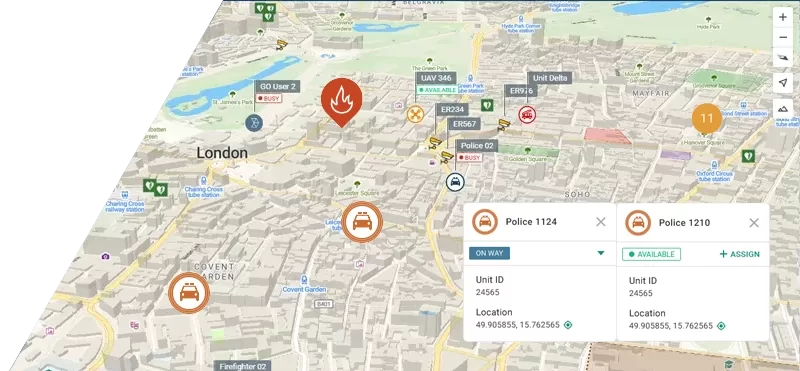

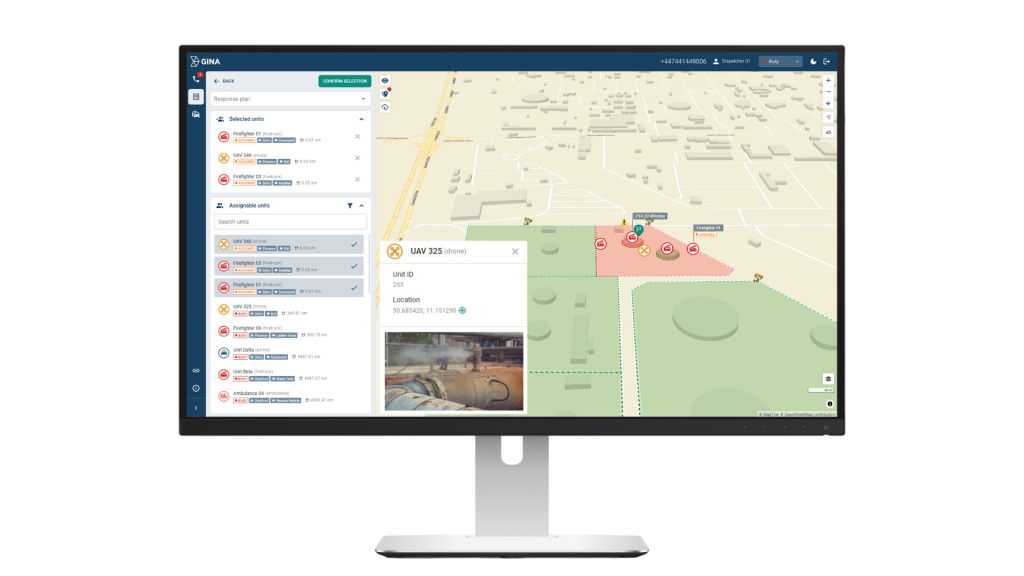

Among the digital tools reshaping the oil and gas sector, Smart CAD (Computer-Aided Dispatch) stands out as a comprehensive safety and coordination platform. It provides organizations with a centralized system to detect hazards, manage incidents, and coordinate resources in real time.

Here’s how Smart CAD supports operations:

- Faster Incident Detection and Response

Smart CAD integrates directly with sensors, monitoring systems, and manual reporting channels. Fires, gas leaks, or equipment failures trigger immediate alerts, and the system automatically identifies the nearest available responders, reducing delays when every second count

- Real-Time Situational Awareness

Supervisors and safety officers gain a live view of both people and assets. Workers and emergency vehicles can be tracked onshore and offshore, ensuring resources are deployed where they are needed most. Historical movement data also helps analyze patterns to strengthen preventive measures.

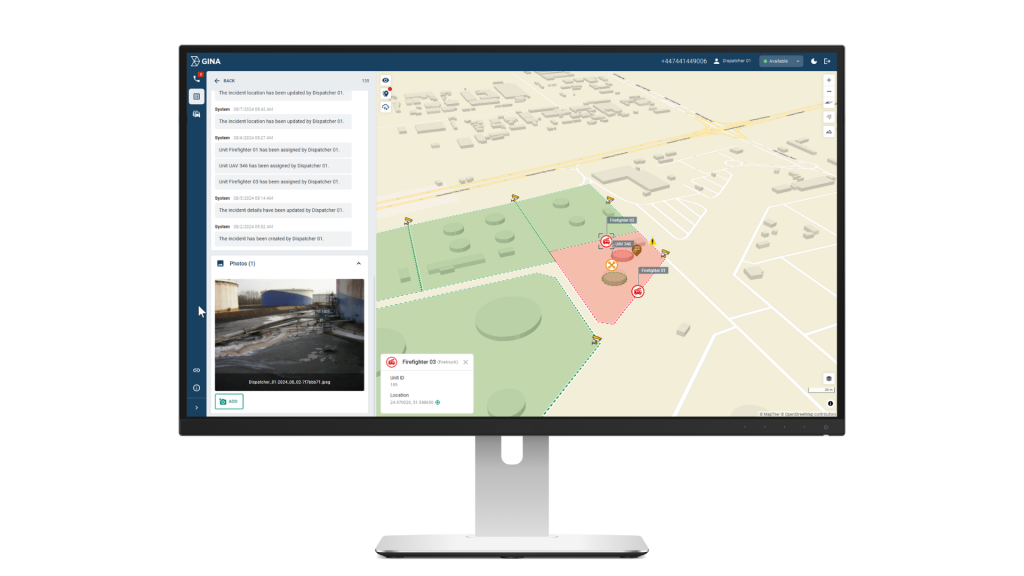

- Seamless Communication

The platform provides push-to-talk voice communication, instant messaging, and multimedia sharing. Photos, videos, and live drone or CCTV feeds can be transmitted directly into the system, giving decision-makers an accurate picture of unfolding situations.

- Automated Workflows and Task Assignment

Once an incident is reported, Smart CAD assigns roles and tasks based on predefined protocols. This reduces confusion, ensures compliance with safety standards, and keeps teams aligned even under pressure.

- Integration with Certified Rugged Devices

In high-risk areas where standard phones or radios are unsafe, Smart CAD operates on safe, certified devices. This ensures workers stay connected without compromising their safety.

- Data-Driven Insights and Reporting

Every incident, response time, and communication log is automatically recorded. These records not only support regulatory compliance but also provide valuable insights for audits, training, and continuous improvement.

By combining these features, Smart CAD transforms how safety is managed in oil and gas operations. It doesn’t replace existing safety protocols, it enhances them, providing a unified platform where detection, response, communication, and reporting come together. The result is faster decision-making, stronger coordination, and a safer environment for everyone on site.

Moving Forward with Confidence

Strong oil and gas safety management is about more than compliance, it’s about protecting workers, preventing hazards, and building operational resilience. By combining clear safety standards, regular safety training, and advanced digital solutions, companies can reduce risks, improve safety outcomes, and enhance operational efficiency.

In the oil and gas industry where every second matters, adopting robust safety measures is essential. Organizations that prioritize workplace safety, invest in safety professionals, and embrace modern tools will not only safeguard their people but also secure a strong safety culture.

To explore how these principles can be applied in practice and discover solutions tailored for the oil and gas sector, visit our dedicated landing page for more insights.