Oil and gas asset management software is vital for companies working in one of the world’s most demanding industries. Vast infrastructure networks are spread across remote and often hostile environments – pipelines that cross borders, offshore rigs far from shore, and refineries that function as complex industrial ecosystems.

These facilities depend on thousands of physical assets, each of which must be monitored to avoid costly downtime. When disruptions occur, the consequences are immediate: lost production, rising costs, and potential threats to both safety and the environment.

By providing real-time insights, early warnings, and rapid response tools, asset management software helps operators reduce risk and act with confidence. In this article, we highlight the biggest operational challenges in oil and gas and show how the right technology keeps businesses running smoothly and safely.

Table of Contents

Managing Remote and Complex Infrastructure

Oil and gas companies manage assets of significant scale, often located in remote and demanding environments. Pipelines cross continents, offshore rigs operate in isolation, and refineries function as vast industrial complexes with countless moving parts.

The challenge is clear: monitoring such a vast and complex network is incredibly difficult. Failures often remain hidden until they become critical, and when a problem is finally detected, reaching the site can take hours, or sometimes even days. Every delay increases operational costs, risks safety, and puts operations under pressure.

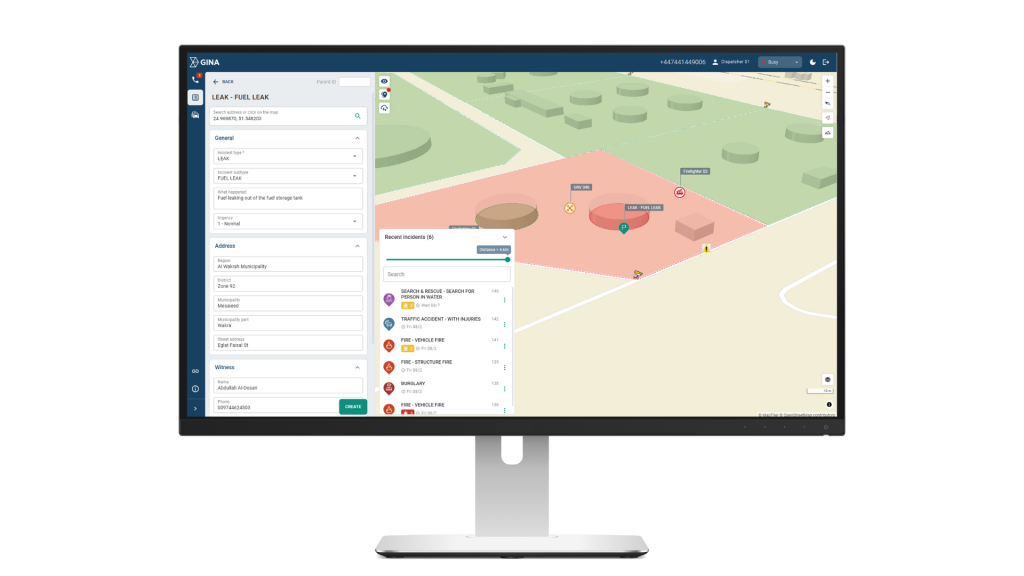

The solution lies in smarter technology. The right software solution gives operators real-time visibility into the health and status of their infrastructure, providing accurate asset information that turns raw asset data into clear insights. Issues are detected early, alerts are triggered instantly, and potential failures can be addressed before they turn into full-blown emergencies.

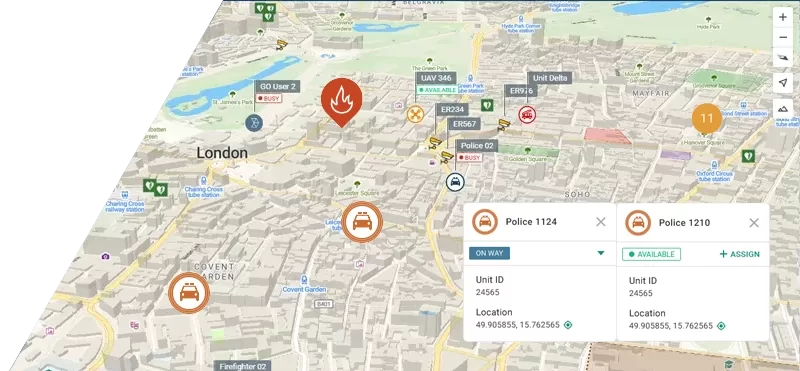

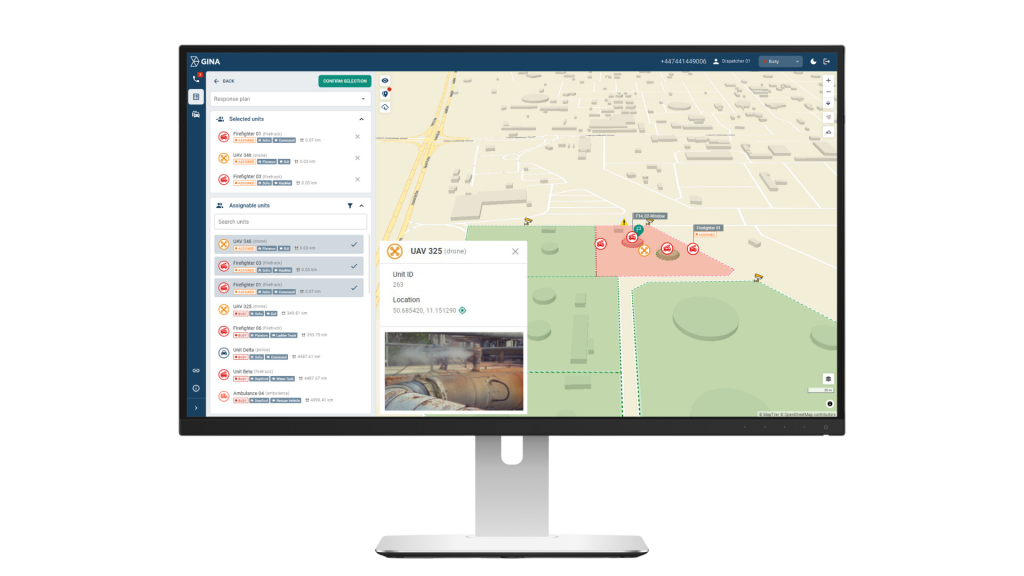

But visibility alone isn’t enough. With Smart CAD, companies can act immediately. Dispatchers see field crews in real time, communicate through push-to-talk, and guide them with live data and navigation. Multimedia sharing ensures decision-makers know the situation before teams arrive. This seamless connection between detection and response keeps operations running, workers safe, and downtime to a minimum.

Reducing Downtime and Preventing Failures

In oil and gas, even the smallest failure can have massive consequences. One faulty pump can bring an entire refinery line to a standstill, while a single valve issue can stop pipeline flow for miles. Every hour of downtime translates into millions in lost revenue.

The real challenge is how quickly companies can react. Failures are often spotted too late, repairs take time to organize, and poor coordination causes unnecessary delays.

The solution is more efficient coordination. Asset management software supports predictive analytics and preventive maintenance, helping companies identify failures before they escalate. Smart CAD ensures that once a potential issue is detected, the response is immediate. Dispatchers instantly know who is closest, which crew has the right skills and equipment, and how to get them on site quickly. By matching the right team to the right task, downtime is reduced, production stays on track, and maintenance processes become far more efficient.

Protecting Workers in Hazardous Environments

The oil and gas industry is one of the most dangerous sectors to work in. Workers face risks such as fires, gas leaks, explosions, and hazardous material exposure. Protecting teams in these conditions is essential, not only for safety but also for business continuity.

Traditional response methods often fall short. In fast-moving situations, delays in communication or poor navigation can put lives at risk.

Here, Smart CAD brings a unique advantage. Beyond simple dispatch, it provides dynamic emergency navigation to guide crews through the safest and fastest routes. Real-time asset tracking shows exactly where teams and equipment are, while live updates keep control rooms aware of evolving conditions to protect critical assets and people alike.

With Smart CAD, crews are guided through the safest routes, decision-makers stay informed in real time, and critical operations move forward without interruption.

Strengthening Security and Meeting Compliance

Oil and gas infrastructure is also a target for theft, sabotage, and cyberattacks. At the same time, operators face strict regulatory demands around safety, reporting, and environmental protection.

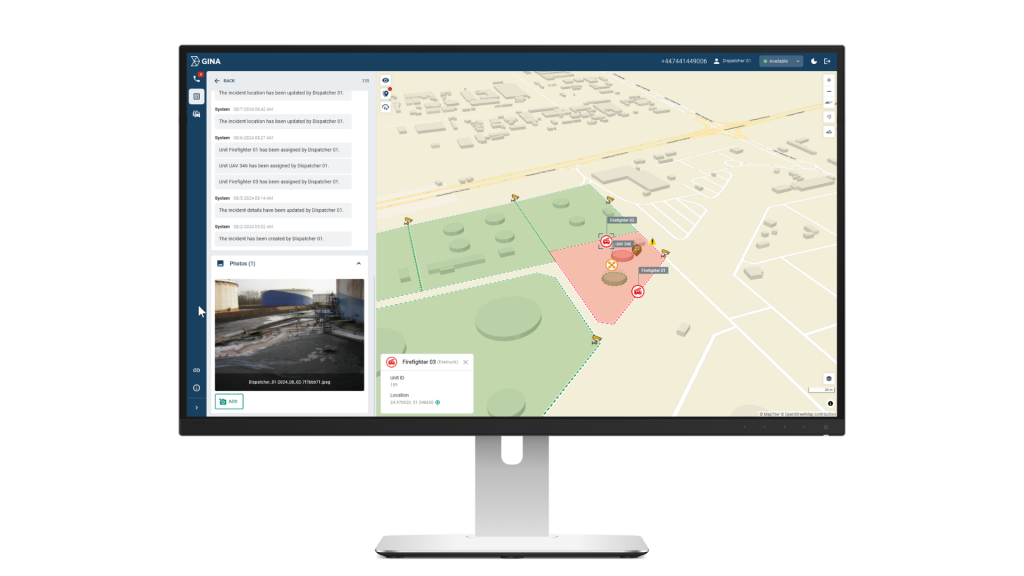

Responding effectively means more than stopping an incident. It requires clear documentation of what happened and how it was handled.

Smart CAD automatically logs every action with timestamps, communication records, and unit locations. This creates a digital record that not only strengthens asset performance management but also provides transparent evidence for audits and regulators. Companies can demonstrate compliance while proving that incidents were managed swiftly and effectively.

Real-World Scenarios: How It Works in Practice

Scenario 1: Refinery Pump Failure

At a refinery, predictive maintenance systems detect a pump showing signs of overheating. Without coordination, production might be interrupted for hours. With Smart CAD, the nearest maintenance team is dispatched instantly, guided to the site, and supplied with live data, extending overall asset life. The pump is fixed within minutes, avoiding a costly shutdown.

Scenario 2: Remote Pipeline Leak

Sensors detect pressure loss on a remote section of pipeline. The system triggers an alert, and Smart CAD automatically deploys the closest response team. Drone footage is streamed back to the control center, giving leaders a live view of the operation. The leak is contained quickly, minimizing environmental damage and financial loss.

These examples show how software and coordination together turn risks into controlled responses.

Smarter Operations With Oil and Gas Asset Management Software

Smart CAD empowers oil and gas companies to operate with greater safety, operational efficiency, and resilience. In an industry where even small disruptions can lead to huge financial and safety consequences, having the right software is critical. Smart CAD delivers the speed, clarity, and control needed to keep operations running without interruption.

Some of the features that make it invaluable for oil and gas include:

- Real-time visibility of crews, vehicles, and assets across pipelines, rigs, and refineries.

- Instant push-to-talk communication to keep teams connected in remote or hazardous environments.

- Dynamic navigation that guides responders through the fastest and safest routes.

- Multimedia sharing of photos, videos, and drone feeds for faster, better-informed decision-making.

- Automatic compliance records with timestamps, communication logs, and incident details.

The impact is clear: workers are safer, downtime is minimized, and critical operations continue even under pressure. By ensuring every alert leads to swift and coordinated action, Smart CAD provides oil and gas companies with more than just efficiency, it delivers confidence.

For an industry where every second counts, Smart CAD is not simply an advantage. It is the decisive link between detection and response, helping organizations safeguard people, assets, and the future of their operations.

To learn more about how Smart CAD supports the specific needs of oil and gas companies, visit our dedicated oil and gas landing page and discover practical examples, use cases, and results from the field.