Mine safety management system effectiveness is rarely defined by the first alert alone. The real impact is shaped in the minutes that follow, how quickly the situation is verified, whether teams operate from the same current information, and how clearly decisions are recorded and shared. When incident control is weak, uncertainty spreads across dispatch, supervisors, and field teams, and the operational cost grows even if the initial event is contained quickly.

Table of Contents

The Hidden Cost of Poor Incident Control in Mining

In many cases, the biggest cost is not the incident itself, but the time lost while teams confirm what is happening, assign clear ownership, and decide when it is safe to return to normal operations. When leadership cannot verify conditions with confidence, stand-down decisions are delayed and production holds last longer than necessary. When dispatch lacks a clear view of resource status, allocation becomes less precise and coordination slips into repeated check-ins and interruptions, extending disruption and increasing workload across the operation.

Typical hidden costs include:

- Extended downtime caused by slow verification, delayed stand-down, and restarts that take longer because nobody wants to move ahead without clear confirmation.

- Inefficient resource deployment when too many assets are drawn into one event, crowding limited routes and leaving other parts of the site with thinner coverage.

- Duplicated effort due to unclear tasking and updates that arrive across different channels.

- Increased exposure to risk as responders and operational staff remain longer in uncertain or restricted areas.

- Reduced operational productivity when coordination relies on repeated status checks and interruptions rather than a shared, continuously updated operational view.

- Higher administrative workload since incident timelines must be rebuilt afterward for reporting, audits, or claims.

The cost also shows up later. When the incident record is incomplete, reviews depend on recollection instead of a clear timeline. Key decisions and priority changes become harder to explain, so corrective actions stay superficial and similar incidents are more likely to repeat.

What a Mine Safety Management System Should Include

A mine safety management system is not just about compliance documents and training records, it also needs operational control under pressure. The aim is to keep everyone working from the same up-to-date information as the situation changes, so different teams can act at the same time without giving conflicting instructions.

Shared Operational Log

Storing notes is not enough. Communication, tasking, and procedure tracking should be connected in one place, so everyone works from the same current information, including during shift handovers.

Smart CAD supports a shared operational log where radio and digital communications are tied to tasking and operational checklists. Dispatch can issue clear instructions, track progress, and confirm completion while keeping actions connected to the incident timeline. This reduces misunderstandings, limits duplicated effort, and makes stand down decisions easier because completion is visible, not implied.

Geofencing and Access control

A mine safety management system should allow teams to define operational zones, restricted areas, and high-risk locations aligned to real workflows. When a vehicle, contractor, or crew crosses a boundary, the alert should be immediate, location-specific, and tied to operational context.

Smart CAD supports this with geofencing and access control that helps prevent unauthorized access and unsafe movement across pits, haul roads, processing areas, and other sensitive zones. Rather than depending on manual supervision, the system detects deviations early, when they can be corrected with minimal disruption.

Sensor Integration

Verification is where time is usually lost. An alert on its own rarely provides enough context to act, so teams end up piecing together what it indicates, where it is occurring, and what response level is actually required.

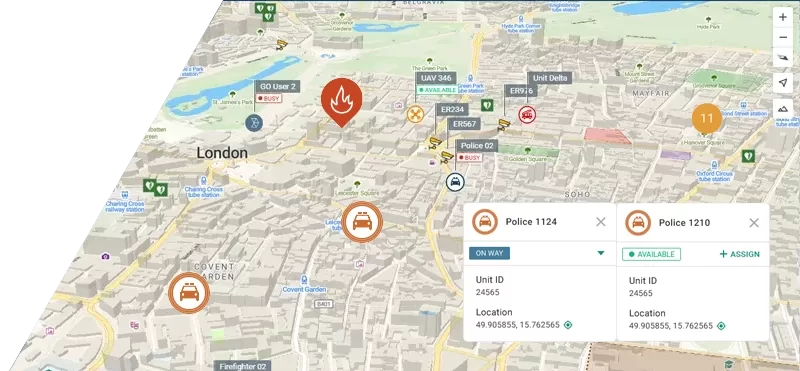

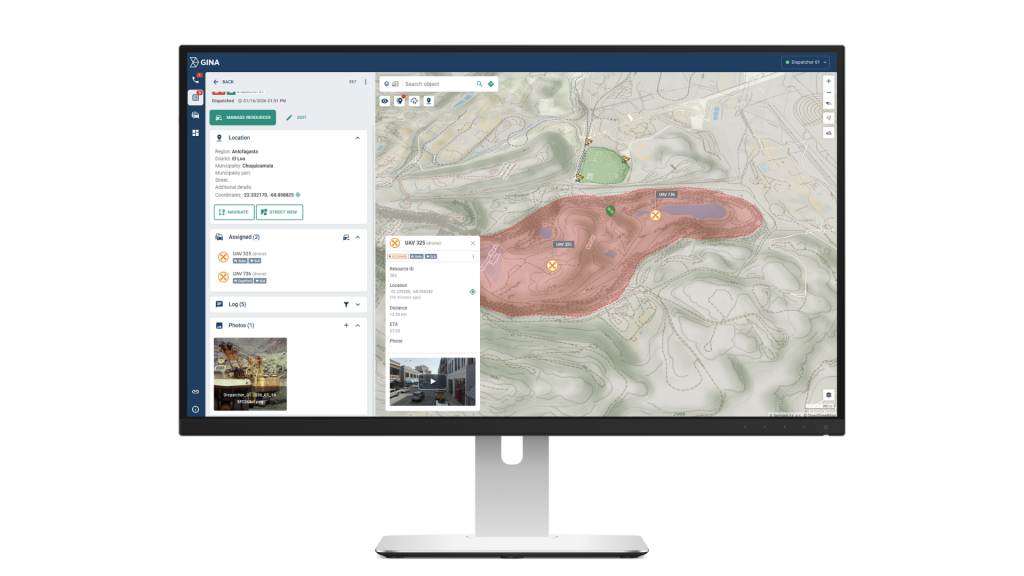

Smart CAD supports integrating CCTV, drones, and environmental sensors into one operational view, where events like perimeter breaches or gas leak indicators trigger alerts linked to a location and an incident. That shortens the path from signal to verified action, which is where downtime usually starts shrinking.

Real-Time Resource Visibility

Incident control depends on knowing where assets are, what they are doing, and which ones are suitable to respond, without dispatch guessing based on stale status updates. This is not only about speed. It reduces congestion in hazardous zones, protects haul routes from turning into bottlenecks, and prevents over-response that leaves other parts of the site under-covered.

Smart CAD supports real-time tracking of vehicles, machinery, and assets, linking their position to active incidents and highlighting the closest suitable resources. This improves early decisions, reduces unnecessary movements, and limits disruption beyond the incident area.

Reporting and Compliance

Mining operators are expected to keep reporting and documentation precise and consistent. When incident information is spread across separate tools and channels, reporting turns into manual reconstruction, and audits become a search for missing facts.

Smart CAD supports structured reporting where incidents, actions, and responses are recorded into consistent outputs suitable for internal review, investigations, and compliance needs. The incident closes with a complete, usable timeline already captured, so reviews focus on decisions and controls instead of patching missing information.

Conclusion

Poor incident control does not just create messy records. It extends disruption, drives inefficient deployment, and keeps people in uncertain conditions longer than necessary. A mine safety management system should shorten the path from first alert to verified action, keep responsibility clear, and produce an incident timeline that stands up to review and audit without reconstruction.

Explore how Smart CAD can support your mining operations here.