While safety standards have improved over the years, oil and gas refinery explosions still happen—often with severe consequences for both people and infrastructure. Preventing these disasters isn’t just about equipment. It’s about fast, accurate information and coordinated response.

In this article, we’ll explore the most common causes of refinery explosions—and how modern software makes the difference between disaster and control.

Table of Contents

- Mechanical Failures and Equipment Malfunctions

- Gas Leaks and Accumulations

- Fires and Jet Flames

- Human Error and Improper Procedures

- Intrusions, Sabotage, and Security Breaches

- Domino Effects and Catastrophic Escalation

- Real-World Impact: Measurable Safety Gains

- Operator Fatigue and Human Limitations

- Complex Site Layouts and Poor Situational Awareness

- Why Safety Tech Matters

- Conclusion: Safety Through Speed, Awareness, and Coordination

1. Mechanical Failures and Equipment Malfunctions

Cause

Valves, pumps, compressors, heat exchangers, and pipes can deteriorate, leak, or rupture under high pressure. Failures from corrosion, fatigue, or poor maintenance often lead to releases of flammable materials.

Typical Chain Reaction

A small leak can evolve into a pressurized gas cloud. If it ignites—via a spark or hot surface—it can trigger a massive fireball or explosion, sometimes escalating into a domino effect across the site.

How GINA Helps

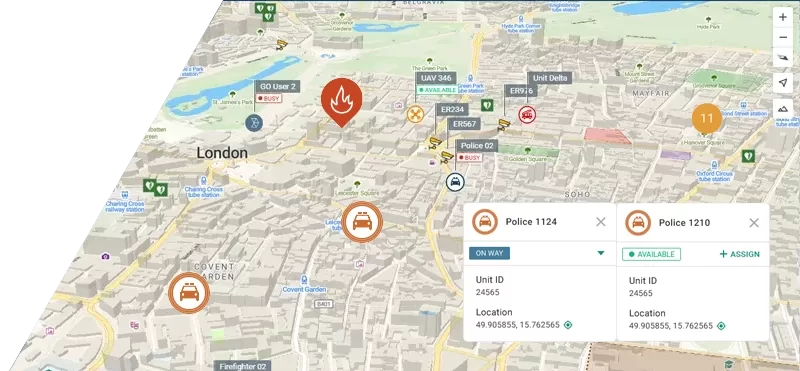

GINA’s Tactical AVL (Automatic Vehicle Location) system integrates with IoT sensors to monitor equipment current state and alert operators instantly when anomalies occur, such as pressure spikes, leaks, or temperature deviations. Automatic alerts than notify control rooms if for example valves or compressors malfunction, enabling immediate action preventing escalations.

2. Gas Leaks and Accumulations

Cause

Hydrocarbon gases (methane, ethylene, propane) can escape from seals, joints, or valves. In enclosed areas, even a small leak may form a flammable vapor cloud. Once a gas cloud reaches a flammable concentration and finds an ignition source, explosions can occur. These may be technically defined as vapor cloud explosions—especially dangerous in confined spaces.

Solution

GINA’s system connects with gas detection sensors to alert responders the moment a gas leak is detected.

Tactical AVL pinpoints the leak’s location precisely on the map, enabling localization of the problem and shutdown of nearby ongoing activities. For many oil and gas companies, obtaining accurate location data in sprawling, complex refinery sectors has traditionally been a significant challenge. With GINA Software, operators can now identify exactly where within the sector the problem is occurring, dramatically improving response time and operational control. The system logs and dispatches technicians automatically via Smart CAD.

3. Fires and Jet Flames

Cause

Ignition sources—like hot surfaces, electrical discharges, or friction—can ignite flammable liquid or vapor, causing sudden flames. Even small fires can lead to jet flames (from pressurized leaks). If uncontrolled, they intensify, damage surrounding equipment, or trigger BLEVE (boiling liquid expanding vapor explosion).

Solution

GINA’s AVL system is able to integrate thermal camers, allowing it to detect early warning signs of fires or jet flames based on abnormal heat signatures, even before visible flames appear. When the system detects an anomaly—heat signature or flame shape via camera—it triggers alarms and dispatches fire units using Smart CAD. Their location and status appear in real time on the map to improve coordination.

4. Human Error and Improper Procedures

Cause

Mistakes like opening incorrect valves, leaving ignition sources near flammables, or deviating from safety protocols frequently trigger incidents. Poor communication during shift transitions increase the risk of incidents. Human errors often directly cause initial leaks, overpressures, and fires, sometimes with catastrophic scale due to procedural lapses.

Solution

GINA’s Smart CAD platform automates dispatching of the responders and ensures all steps are recorded and followed to the letter. Personnel receive immediate in-app notifications. Every action is logged, supporting accountability and faster analyses.

5. Intrusions, Sabotage, and Security Breaches

Cause

Security breaches by unauthorized individuals or groups—internally or externally—can lead to sabotage or theft. Broken pipelines, tampered valves, or equipment sabotage poses grave risk. Beyond direct sabotage, intruders may damage instrumentations or gas pipes, causing leaks that could ignite.

Solution

Tactical AVL location tracking helps to detect route deviations or unusual movements by personnel or vehicles. If someone breaches a restricted area, the system triggers an immediate alert to the control room. Security teams and drones can then be dispatched via Smart CAD. Local camera integration provides real-time situational awareness to counter potential sabotage before it escalates.

6. Domino Effects and Catastrophic Escalation

Cause

An initial incident—like a jet flame—can weaken adjacent structures or equipment, triggering further failures in a chain reaction. Like dominos falling, one failure sparks the next. These cascading failures can convert a minor leak into a refinery-wide disaster, with multiple explosions and fires.

Solution

GINA’s Tactical AVL integrates sensor data and camera alerts across the entire site, enabling cross-site situational awareness. When one incident is detected, the system immediately evaluates risk to nearby areas and restricts movement accordingly. Smart CAD executes coordinated evacuation and response plans tailored to multiple incident zones.

Real‑World Impact: Measurable Safety Gains

From a recent case study in the Gulf of Guinea oil field, where GINA rolled out Tactical AVL across five sites:

- They achieved a 70% faster emergency response in critical scenarios.

- Theft incidents dropped over 40% within the first year thanks to geofencing and real‑time tracking.

Although this example highlights theft and basic emergency response, the same system architecture—real-time sensor integration, geofenced alerts, dispatch workflows, camera analytics—forms a robust defense against explosion sequences in high-risk refinery areas.

7. Operator Fatigue and Human Limitations

Cause

Long shifts reduce alertness, increasing the chance of missed alarms, slow responses, or procedural lapses—especially critical near volatile substances. Subtle early warning signs—pressure changes, small leaks—may be ignored or not acted on quickly due to fatigue. This gives incidents time to escalate.

Solution

GINA’s AVL reduce dependence on human monitoring. Automated alarms ensure no signal is missed, and responders are routed precisely—even during off-hours or shift changeovers. Analytics identify rogue patterns—like repeated threshold crosses—signaling fatigue-prone scenarios, prompting preemptive action.

8. Complex Site Layouts and Poor Situational Awareness

Cause

Refinery sites are spread across vast acres, with complex piping, mobile units, storage tanks, and confined spaces. Monitoring every corner manually is impossible. Lack of awareness can delay acknowledgment of a leak, fire, or intruder, allowing the situation to spiral.

Solution

GINA’s Tactical AVL provides vehicle and personnel locations, hazard zones, no-go areas, and live camera feeds, all on a single platform. Smart CAD dispatches the closest, most equipped responders while logging contamination zones and evacuation paths. This unified visualization enhances command staff’s response and situational coordination.

Why Safety Tech Matters in Preventing Oil and Gas Refinery Explosions

Individually, fire alarms, pressure sensors, and GPS tracking systems contribute to safety. But the power of integration—unifying sensor streams, mapping, alerts, dispatch, communication, and post-event logging—is what stops small issues before they become refinery-wide explosions.

GINA Software delivers this approach. Its Smart CAD and Tactical AVL systems are built to:

- Connect real‑time sensor inputs (pressure, gas, motion, man-down)

- Trigger automated geofencing alerts

- Present live situational awareness via maps and video

- Enable rapid, intelligent dispatching

- Log every event for post‑incident review and compliance

Further Reading

To explore how GINA helps manage other emergency scenarios like terrorist threats, personal protection, or industrial disasters, visit their Solutions and Products pages for Smart CAD, Tactical AVL, and GINA Apps.